The automatic waste segregation machine is a device that is used to retrieve useful products from waste materials. Beston Group has a long history of delivering waste recycling plants to many counties across the world such as South Africa, the Philippines, and Indonesia. It is also urgent and necessary to start waste management in many countries in the world.

Waste products cause serious environmental implications such as environmental degradation, global warming, climate change, depletion of the ozone layer, and undesirable accumulation of toxic gases in the lower layers of the atmosphere. On top of that, waste products that are not handled well result in water pollution, air pollution, and land pollution. However, the Beston waste segregation machine is a vital piece of equipment that helps keep the menace of pollution at bay.

Advantages of Automated Waste Segregation System

1. Conversion of Wastes Into Treasure

Several beneficial products are obtained from waste products during the waste sorting process. Plastics, metal pieces, and organic compounds are examples of waste products that can be converted into beneficial products that have value. Additionally, most products that are reclaimed from garbage have high economic benefits.

2. Maximization of Land Use

Large pieces of land are usually rendered uneconomical because of the massive piles of garbage that fill them. Beston automatic waste segregation machine helps to reclaim these wastelands by reducing the sizes of the garbage piles. The process leaves more land for other economic activities such as farming and agriculture.

3. Protection of the Environment

Waste products contain hazardous elements such as mercury, lead, and cadmium, which are toxic substances with severe environmental implications. The Beston automated waste segregation system helps to reduce the toxicity of these substances to protect the environment and its inhabitants from the adverse effects of pollution.

4. Creation of Employment Opportunities

The solid waste recycling plant provides a lot of job opportunities for both local and international workers. The plant requires people to work in the production, packaging, and maintenance departments. On top of that, the waste segregation machine creates jobs for engineers who install and troubleshoot the machinery during breakdowns.

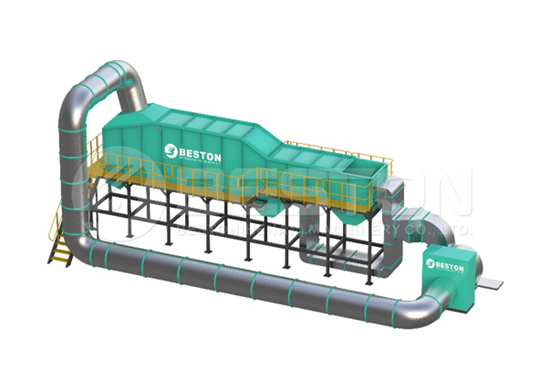

Special Design of Beston Waste Segregation Machine

1. Machine Automation- The automatic waste segregation machine has incorporated advanced systems that eliminate manual work. Elimination of manual labor ensures that human mistakes are excluded from the waste sorting plant as much as possible.

2. Eco-Friendly Design- The waste segregation machine is completely sealed to prevent toxic substances from escaping into the environment. The feature makes the plant the best choice for both private and government parastatals.

3. Presence of a Deodorization System- The system ensures that the working environment is as clean and conducive for workers as possible. The system also ensures that the health conditions of the people working in the plant are safeguarded.

4. Efficient Design- The automated waste segregation system if efficient at recovering valuable commodities from almost all waste products. Since the plant is programmed, the waste segregation process is performed with computerized systems that work with particularly high efficiencies. The high efficiencies contribute to the high overall efficiency of the waste sorting plant.

5. Affordability- Besides the incorporation of world-class automated systems, the Beston machine is sold at an affordable price that can comfortably fit your budget.

Working Principle of Beston Waste Segregation System

The waste sorting plant works as explained below to produce useful products:

The waste materials are put in a plate feeder that pushes them to the uniform feeder, which distributes the materials uniformly.

The materials are then transmitted to the rotating screening machine which separates the materials into two; materials larger than 50mm and materials smaller than 50mm.

Waste materials smaller than 50mm are mainly organic materials, while those larger than 50mm are mostly textiles, plastics, stones, and rubber.

The resultant waste materials are passed through a magnetic separator that eliminates all the iron products from the materials.

The striking advantage of the automatic waste segregation machine from Beston is that the above processes can be customized to meet each specific sorting need.

Utilization of Recovered Waste Materials

The recovered materials can be handled differently, as stated below:

1. Plastics can be sold directly in the market or recycled for use in a waste pyrolysis plant.

2. Organic materials can be used to make fertilizers that are used to enhance the productivity of the soil.

3. Metallic objects can be reprocessed to make new valuable iron products such as plates and spoons.

4. Bricks can be reprocessed to make construction materials.

5. Tiles can be processed again to make elegant tiles that can be used to enhance the aesthetics of buildings.

In summary, the benefits of Beston machinery cannot be exhausted. It is crucial to understand the key benefits of the Beston automatic waste segregation machine so that the right choice is made when selecting a plant to help in recycling waste products.