There are many things to consider when searching for the ideal garbage sorting machine. The automation level, the segregation modules and the specific functions can all make a huge difference in terms of efficiency and safety. Here are a few of the challenges of shopping around for the garbage sorting machine.

Containing the bad smells is one of the main concerns when it comes to choosing a garbage sorting system. There are local rules and regulations regarding this issue, so you’ll have to check with your local authorities to find out all these details. Environmental safety is extremely important, and so is the health and the safety of your workers. This means that you’ll have to ask all suppliers of waste sorting equipment for details on their odor containing and neutralizing systems.

The efficiency of your system is another element that can have a direct influence on your choice. If you can afford it, you can go for a fully automatic waste segregation machine that will require very little to no manual work. This is perhaps one of the best methods to keep operating costs at a reasonable level. Anyway, you’ll have to compare the cost of automatic systems with the cost of using manual workers at those stages where the two options are possible. You can, for instance, choose to remove the garbage from the plastic bags that contain it either by using manual workers or an automatic bag removal machine. As odd as it may seem, the automatic process is more accurate than the manual one. Besides, you won’t have to pay that many employees.

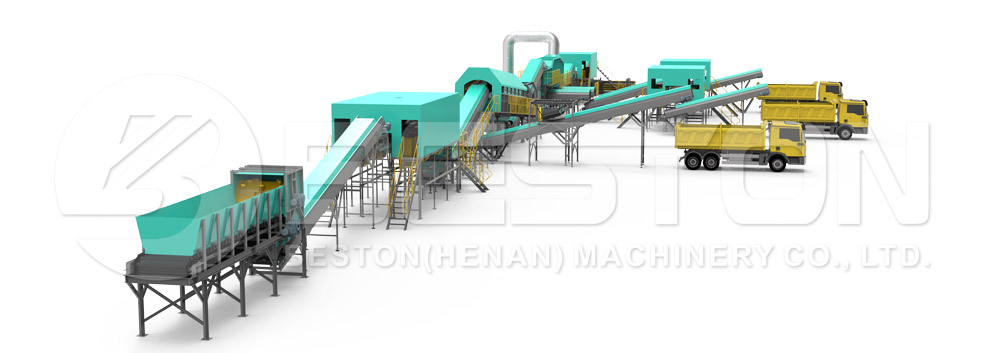

All these processes require different conveyor systems. Designing these conveyors is yet another challenge to overcome. Different materials require different types of conveyor belts. Very heavy items, for instance, usually require metallic conveyors instead of the conventional rubber belts. You’ll need to discuss all these details with the manufacturers of garbage sorting machines in order to be able to make an informed choice. Find more on the blog: http://bestonchina.weebly.com/.

Last but not least, you’ll have to make sure you find the best possible deal. This means that you should ask at least two or three suppliers for a quote. Once you get your quotes, you need to compare them side by side to choose the winner. If you’ve already done your homework during the research stage, this is going to be an easy choice.