Charcoal making machine uses the carbonization process to turn biomass waste material into charcoal. This reduces over 95% combustible waste. Along with protecting the environment and reducing energy consumption, it also helps in creating huge profits.

Features of Charcoal Making Machine

1. Pollution Free

This charcoal making machine doesn’t emit any pollutants as it uses an indirect cooling system.

2. High calorific gas value

It has a high calorific value gas, which is three times the regular straw gas. This improves the efficiency of the work and incurs a low cost.

3. High profits

With the high demand for biomass charcoal and tar in the market, these plants have good market profits.

4. Inexpensive and quality raw material

The raw material used in these machines is low price materials, like charcoal, husk, wood chips, sawdust, etc, which are commonly used in day to day life.

5. Low operating cost

The machine has a continuously operating system, which reduces heat loss, which further reduces the operating cost. Click here to know more about Beston Machinery.

6. Continuous production

This machine has an automatic assembly line, which means the raw material is being fed at one end and the final product is discharged at the other end continuously. This helps in saving fuel and work is carried on efficiently.

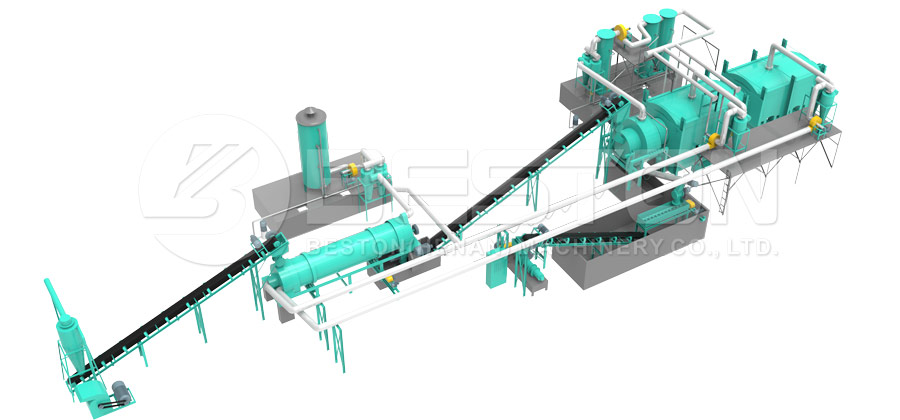

Components of Charcoal Making Machine

The charcoal making machine consists of a casing, de-dusting system, cooling system, sealing device, carbonizing machine, drier, and auxiliary equipment.

The charcoal furnace has a reliable casing which protects the temperature inside the furnace. The casing also shields workers from the machine.

The gas generated by the furnace through carbonization can be purified with the help of the de-dusting system, which has a spray dust collector and cyclone dust collector.

The charcoal that is discharged finally may have high temperatures. In order to ensure safety, a cooling system is installed, which cools the charcoal before it is being discharged.

The sealing device helps in keeping the workshop clean and safe for production.

Final Products of Charcoal Making Machine

1. Charcoal

This machine produces high calorific value charcoal. It is used in industrial melting as fuel. Charcoal can also be used for cooking. It is used as fertilizer, as it is rich in micro-elements like calcium, phosphorous, manganese, zinc and nitrogen. It improves the soil quality and the yield of the crops.

2. Tar

It has more than 300 chemical elements and is used in making waterproof material. It is also used in many medicinal applications.

3. Wood Vinegar

Wood vinegar is used in skin diseases treatment. It is also used in making food preservatives and also acts as an anti-inflammatory substance.

Charcoal Carbonization Process

The steps involved in Charcoal Carbonization are:

1. Pretreatment

It is ensured that the moisture in the raw materials does not exceed 20%. The size of the material should be maintained less than 50mm. If the moisture content and size of the raw material does not meet the requirements of the carbonization process, it needs to be treated in a drier and crushed in a crusher.

2. Carbonization

After the raw material is pretreated, it is then transferred to the coconut charcoal making machine. It is then heated for 30 minutes until the temperature reaches 100. Then the temperature starts increasing and reaches around 400 to 600, where the biomass will be converted into charcoal and gas (combustible). It usually takes around 20 minutes for the carbonization process. The cooling system then collects the charcoal for decreasing its temperature. The gas that is obtained, is further processed.

3. Smoke Discharge

The spray dedusting system helps in removing the harmful content in the combustible gas, as the carbonized gas contains sulfur. The cleaned gas is then condensed to tar and wood vinegar by the condenser. The combustible gas can be recycled to produce fuel for the heating furnace.

4. Charcoal Enrichment

After the charcoal is cooled down to 30/span>C, it is directly collected.

With regular maintenance and repair, the charcoal making machine can be avoided from any potential damage and used in generating huge profits. There are different machines available with different capacities, to choose depending on the plant size. The biochar production equipment has a life span around 6-8 years.

Charcoal making machine proves to be providing high calorific value gas, with a low maintenance cost, pollution free and is highly profitable.