Plastic pyrolysis emerges as a key player, strategically positioned in the circular economy framework. This innovative process involves the thermal degradation of plastics at elevated temperatures, excluding the presence of oxygen. As we navigate the complexities of contemporary waste disposal challenges, exploring the facets of plastic pyrolysis plant projects, intricate reactor design, and considerations like the plastic pyrolysis machine price becomes imperative.

Unraveling the Circular Economy Nexus

At the heart of the circular economy lies the principle of resource efficiency and reutilization. Plastic waste, omnipresent in our modern lives, poses a significant environmental conundrum. Here, pyrolysis steps into the limelight, offering a transformative solution by breaking down plastics into valuable constituents.

The Pyrolysis Process Unveiled

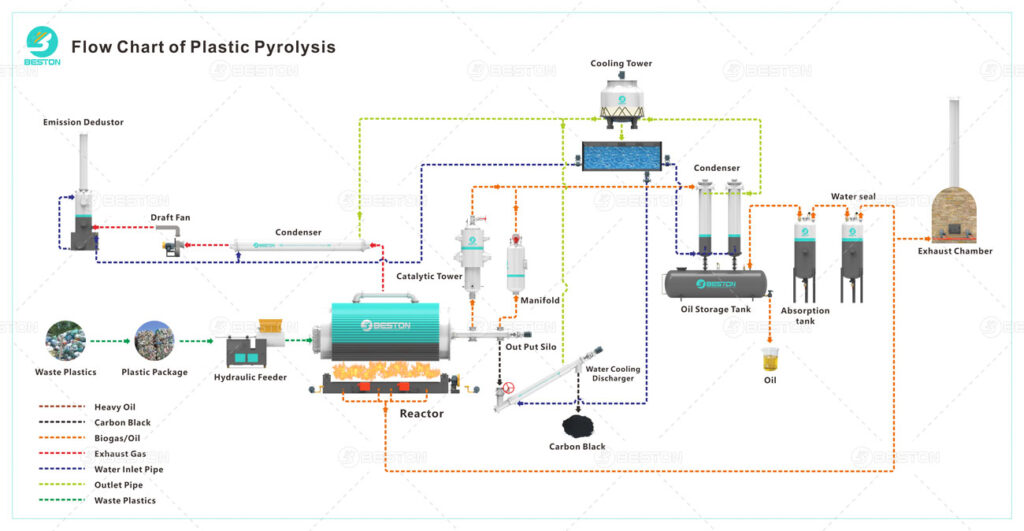

Pyrolysis, as applied to plastics, initiates a controlled decomposition, liberating the material from its polymeric structure. The absence of oxygen prevents combustion, ensuring a clean and efficient process. The resulting outputs comprise pyrolytic oil, a versatile liquid fuel, and various by-products like carbon black and gases.

Long hydrocarbon chains within plastics undergo thermochemical cracking, leading to a spectrum of hydrocarbon fragments. These fragments are subsequently condensed into pyrolytic oil, a substance garnering attention for its potential in fuel applications. This oil, akin to a phoenix rising from plastic ashes, becomes a valuable asset in our quest for sustainable energy solutions.

Innovative Reactor Designs: Catalysts for Progress

Critical to the efficacy of plastic pyrolysis are reactor designs that optimize the thermal decomposition process. The intricate dance of temperature, pressure, and residence time demands a tailored apparatus. In the realm of sustainability, continuous improvement in plastic pyrolysis machine reactor design is crucial.

Continuous Pyrolysis: A Seamless Symphony

A key innovation lies in the development of continuous plastic pyrolysis machines. These marvels of engineering seamlessly process plastic waste without interruption. The continuous nature ensures a consistent output stream, contributing to operational efficiency. As plastics enter the reactor, they embark on a continuous journey of transformation, navigating through optimal temperature zones.

Small-Scale Pyrolysis: The Localized Revolution

Concurrently, small-scale plastic pyrolysis machines address the need for localized waste management. These compact units bring the process closer to the source of plastic waste generation, minimizing transportation emissions and enhancing the feasibility of community-level initiatives. In doing so, they serve as catalysts for sustainable change, particularly in regions grappling with limited resources.

Economic Dimensions: Decoding Machine Costs

Amidst the grand tapestry of circular economy strategies, the plastic pyrolysis machine price assumes a pivotal role. Understanding the economic feasibility of pyrolysis plants is essential for widespread adoption and long-term success.

Navigating Investment Landscapes

Investing in a plastic pyrolysis plant necessitates a comprehensive understanding of costs and potential returns. The plastic pyrolysis plant project report becomes a guiding document, outlining financial projections, technological specifications, and environmental impact assessments. This report, a beacon for prospective investors, underscores the viability of pyrolysis as an economically sound and ecologically responsible venture.

The Ripple Effect: Environmental Impact

Beyond the economic realm, the environmental ramifications of plastic to fuel machine amplify its significance in circular economy paradigms. The process stands as a vanguard against plastic pollution, offering a sustainable alternative to landfill disposal and incineration.

Mitigating Plastic Pollution

By harnessing the potential of pyrolysis, plastics are not merely discarded but transformed into valuable resources. This metamorphosis significantly mitigates the burden on landfills, reducing the visual and ecological scars inflicted by plastic waste. The circular economy ethos, woven into the fabric of pyrolysis, transforms waste into an opportunity for resource recovery.

Carbon Black: A Second Life

In the alchemy of pyrolysis, the emergence of carbon black adds a unique facet to the circular economy narrative. This finely powdered substance, a by-product of the plastic pyrolysis process, finds applications in myriad industries. From enhancing the durability of rubber products to serving as a pigment in inks and paints, carbon black becomes an emblem of resource optimization.

Looking Ahead: The Pyrolysis Trajectory

As we chart the trajectory of pyrolysis in the circular economy landscape, the intricate dance between technological innovation, economic viability, and environmental stewardship unfolds. Continuous advancements in reactor design and the proliferation of small-scale machines herald a future where plastic waste is not a burden but a reservoir of untapped potential.