Carbonized rice hulls have been a great advantage to modern agriculture by providing a cost-effective and eco-friendly alternative to the traditional, less durable materials that are used in animal feed. The benefits of using carbonized rice hulls for livestock feed include improved weight gain, increased milk production, improved fertility rates, and reduced methane emissions from livestock. In addition, carbonized rice hulls are a renewable resource that can be used to improve soil health and reduce the need for chemical fertilizers.

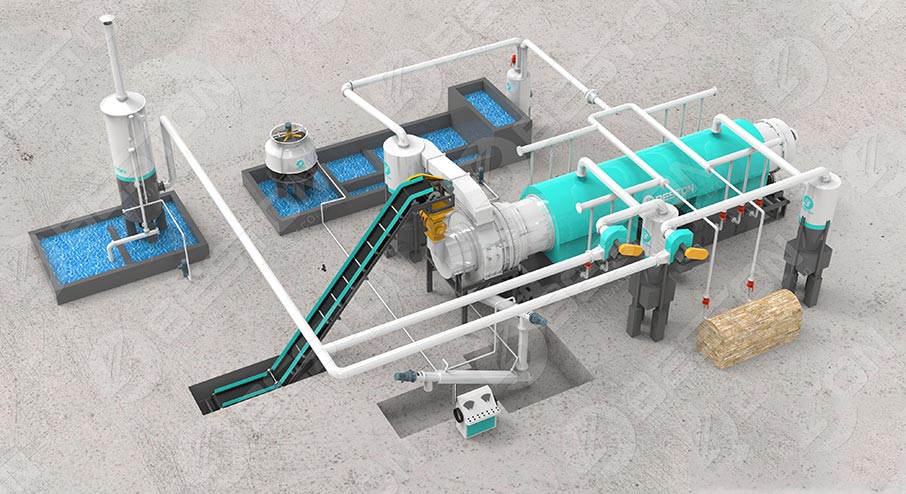

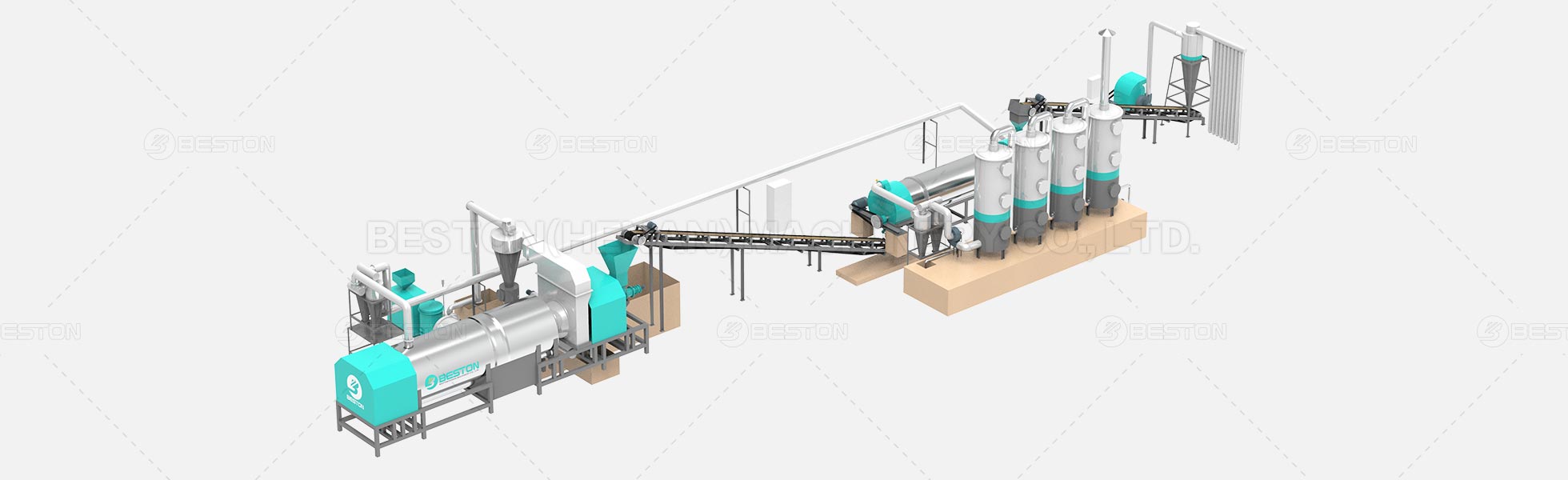

Rice hulls are made from the outer husks of rice and can be carbonized (maquina para hacer carbon vegetal)by heating them up to a high temperature without oxygen. This makes the rice hulls more durable and less prone to spoilage, which is why they are a great alternative to materials like wood shavings or sawdust that have been traditionally used as animal bedding material in livestock feed production.

The heat causes the husk to turn black, which is when they’re ready to use as a feed additive. The black color is an indication of the high carbon content, which is what makes them so beneficial for modern agriculture. They are a low-cost alternative that has been shown to increase crop yields by up to 25%.

Additionally, carbonized rice hulls can also absorb and neutralize odors and harmful chemical components released into the air during livestock production facilities such as poultry farms or dairy processing plants.

In terms of environmental benefits, carbonized rice hulls can help reduce greenhouse gas emissions and improve soil health. By replacing traditional materials like peat moss and bark with carbonized rice hulls, you can reduce your reliance on non-renewable resources while enhancing the soil’s ability to retain moisture and nutrients. Carbonized rice hulls are also an effective way to improve air quality in greenhouses, as they help filter out harmful gases like ammonia and methane.

Additionally, they add nutrients to the soil that may have been lost due to commercial fertilizers or pesticides. This helps to reduce the need for chemical fertilizers, which can be harmful to the environment(hornos metalicos para hacer carbon).

Who Uses Carbonized Rice Hulls Today?

The use of carbonized rice hulls is becoming more and more popular among livestock producers as they become more aware of the benefits. Some of the largest users of carbonized rice hulls include poultry farmers, dairy processors, and feedlot operators.

In fact, according to a study by Iowa State University, the use of carbonized rice hulls has increased by more than 200 percent among livestock producers since 2012.

The benefits of using carbonized rice hulls(beston company) for animal feed are too many to ignore, and as the technology continues to evolve, it is likely that their use will become even more widespread. So if you’re looking for an environmentally friendly and cost-effective way to improve your livestock production, look no further than carbonized rice hulls.

The Future of Carbonized Rice Hulls and How it Could Change the World as We Know It

Carbonized rice hulls have a promising future in the world of organic farming. In recent years, their popularity has been growing exponentially among livestock producers who are looking for cost-effective and eco-friendly alternatives to traditional animal feed materials.

But it’s not just farmers that will benefit from these – carbonized rice hulls(usos del biocarbon) could also be used to improve the food we eat. For example, they can be mixed with soil to help grow healthier and more nutrient-dense crops that would otherwise have a limited shelf life prior to being harvested.

In other words, this sustainable resource could revolutionize how farmers grow their produce all around the world by making it easier for them to create higher quality, more nutrient-rich food.

This, in turn, would help to improve the overall health of people living in developing countries who are struggling to get the nutrients they need from their diets. While carbonized rice hulls have been used primarily for livestock feed production thus far, there is no telling what the future may hold for this versatile and sustainable material.