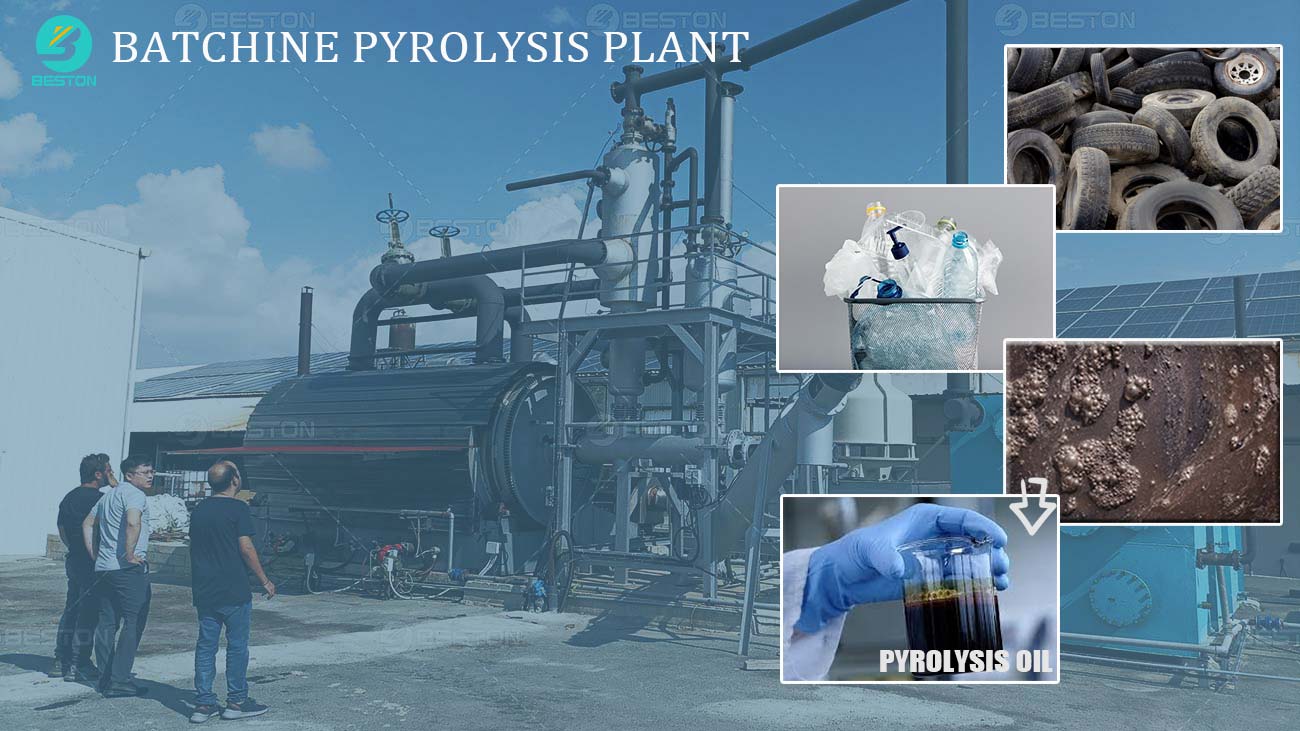

Pyrolysis plants take the spotlight, offering a cutting-edge solution for converting organic matter into valuable resources. Yet, navigating the complexities of this process presents its own set of hurdles. Tackling issues like wastewater management, emissions control, and solid waste generation demands a creative blend of tried-and-tested techniques and forward-thinking strategies.

Managing Wastewater: A Delicate Balancing Act

Wastewater from a large/small pyrolysis machine contains a cocktail of organic compounds, heavy metals, and other contaminants, necessitating comprehensive treatment strategies. Conventional methods such as sedimentation and filtration play a role, but advanced techniques like membrane bioreactors and electrocoagulation offer enhanced efficiency in removing pollutants.

Furthermore, the integration of advanced oxidation processes (AOPs) such as ozonation and photocatalysis proves instrumental in breaking down recalcitrant organic compounds, ensuring the quality of discharged water meets regulatory standards. By employing a combination of physical, chemical, and biological treatment methods, pyrolysis plant operators can mitigate environmental impact and safeguard water resources.

Tackling Emissions: A Path to Cleaner Air

Emissions from pyrolysis plants pose a significant challenge, as they often contain volatile organic compounds (VOCs), particulate matter, and greenhouse gases. To combat this, gas scrubbing systems utilizing activated carbon adsorption and wet scrubbing techniques emerge as effective means of capturing pollutants before release into the atmosphere.

Additionally, the adoption of catalytic converters and thermal oxidizers facilitates the conversion of harmful compounds into less toxic forms through catalytic combustion and thermal decomposition processes. This not only reduces emissions but also contributes to energy recovery and process efficiency, aligning with the principles of sustainable waste management.

Confronting Solid Waste: From Residue to Resource

Solid waste generated by waste plastic pyrolysis plant, often in the form of char, presents both challenges and opportunities. While conventional disposal methods like landfilling remain prevalent, innovative approaches aim to repurpose char as a valuable resource.

Techniques such as pyrolysis gasification and biochar production transform char into syngas or biochar, which find applications in energy generation and soil improvement, respectively. Moreover, carbonization processes enable the conversion of organic waste into biochar, mitigating the environmental impact of waste disposal while contributing to carbon sequestration efforts.

Embracing Sustainable Principles: A Holistic Approach

At the heart of effective waste treatment lies the integration of sustainable principles into continuous/semi-continuous/batch pyrolysis plant operations. This entails minimizing environmental impact and maximizing resource recovery and energy efficiency throughout the process chain.

By prioritizing closed-loop systems and circular economy principles, pyrolysis plant operators can minimize waste generation and optimize resource utilization, fostering a more sustainable and resilient waste management ecosystem. Furthermore, stakeholder engagement and collaboration facilitate knowledge sharing and innovation, driving continuous improvement in waste treatment practices.

Charting the Course Ahead: Innovation and Collaboration

As the demand for sustainable waste management solutions continues to rise, the pyrolysis plant industry stands at a pivotal juncture. By embracing innovation and collaboration, stakeholders can unlock the full potential of pyrolysis technology while addressing environmental challenges and advancing toward a circular economy model.

Looking ahead, ongoing research and development efforts hold the key to enhancing waste treatment efficiency, reducing environmental footprint, and expanding the scope of resource recovery from tyre/plastic waste pyrolysis process. With concerted action and a commitment to sustainability, pyrolysis plant operations can chart a course toward a greener, more resilient future for waste management.

In conclusion, the treatment of wastewater, emissions, and solid waste from pyrolysis plants requires a multifaceted approach grounded in technical expertise, innovation, and sustainable principles. By leveraging advanced treatment methods and embracing circular economy principles, pyrolysis plant operators can mitigate environmental impact, optimize resource utilization, and pave the way for a more sustainable waste management paradigm.