The shift toward automation in manufacturing has revolutionized numerous industries, and the egg tray production sector is no exception. A fully automatic egg tray machine offers remarkable benefits, improving efficiency, reducing labor requirements, and ensuring higher output quality. These machines stand as vital components for companies looking to optimize their production lines while minimizing environmental impact.

Increased Production Efficiency

One of the primary advantages of a fully automatic egg tray machine is its ability to produce a large volume of trays with minimal human intervention. Traditional methods of egg tray production, often labor-intensive, struggle to keep pace with modern industry demands. In contrast, an automated system operates continuously, producing hundreds or thousands of trays per hour depending on the machine’s capacity.

This significant increase in output directly contributes to better operational efficiency. Companies can fulfill larger orders in less time, increasing their competitiveness in the market. For manufacturers serving high-demand sectors, such as the food and agricultural industries, this is a crucial benefit. The fully automated egg tray machine streamlines the production process, freeing up time and resources for other essential business activities.

Reduced Labor Costs

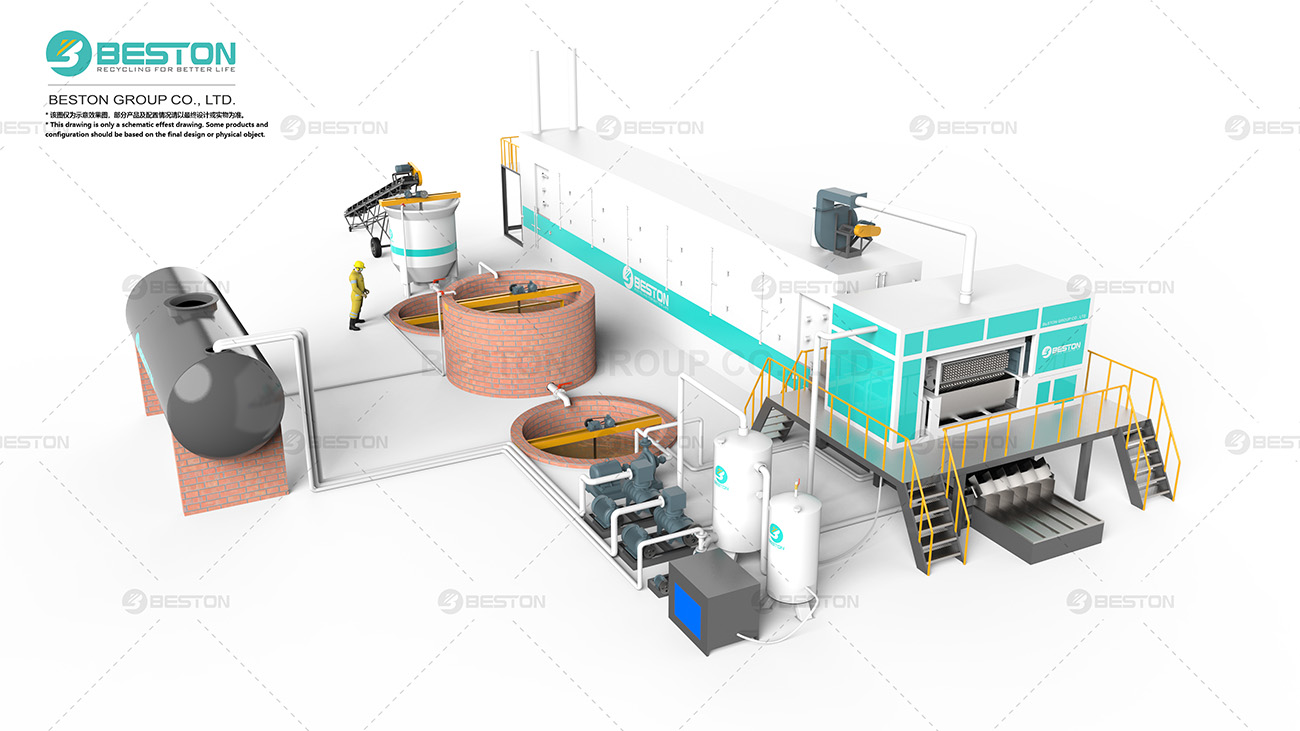

Automation also reduces labor requirements. Traditional egg tray production often requires a large workforce for tasks like pulp preparation, tray molding, drying, and packaging. A fully automatic egg tray machine consolidates many of these tasks into one seamless process, requiring minimal manual oversight.

With fewer workers needed to operate the machinery, companies can significantly cut labor costs. This is particularly beneficial for operations in regions where labor costs are high. Additionally, the machine’s consistent and reliable performance reduces the risk of errors commonly associated with manual production, leading to fewer product defects and less material waste.

Enhanced Consistency and Quality Control

Maintaining consistent product quality is a major concern for manufacturers. Fully automatic paper egg tray making machine is designed to ensure that each tray meets strict quality standards. By automating the molding, drying, and packaging processes, the machine reduces variability and maintains uniformity across batches.

Automation also allows for better monitoring and control over critical parameters such as pulp thickness, drying time, and tray dimensions. This precision is essential in maintaining the structural integrity of the egg trays, ensuring they can adequately protect the eggs during transportation and storage.

Moreover, the consistency offered by fully automatic machines directly translates into customer satisfaction. Buyers expect uniform quality, especially when sourcing in bulk. Automated production helps meet these expectations reliably, reducing the likelihood of complaints or returns due to product defects.

Energy and Resource Efficiency

Another significant advantage of a fully automatic egg tray machine is its optimized use of energy and resources. Many machines are designed to recycle water used in the pulp-making process, reducing overall water consumption. Additionally, the drying systems in these machines are engineered to minimize energy use, making them more eco-friendly compared to older, less efficient models.

These energy-efficient features not only contribute to a reduced environmental footprint but also lower operational costs. With rising energy prices and increasing pressure on companies to adopt sustainable practices, investing in an energy-efficient egg tray machine offers long-term financial and environmental benefits.

Minimal Waste and Environmental Impact

The fully automatic egg tray machine typically operates using recycled paper as the primary raw material. This approach reduces the need for virgin pulp, promoting the use of post-consumer materials that might otherwise end up in landfills. The machine converts waste paper into durable, biodegradable egg trays, effectively contributing to waste reduction. For more information please contact Beston Group Ltd.

In addition to recycling materials, modern machines often feature systems that recycle water used during production. This water can be filtered and reused within the machine, significantly reducing wastewater output. These features align with global trends toward more sustainable manufacturing practices, providing companies with an environmentally responsible solution for their production needs.

Flexibility in Design and Customization

Fully automatic egg tray machines are highly versatile, allowing manufacturers to produce trays of various shapes and sizes. The machine can be adapted to create custom molds, catering to specific customer needs beyond egg trays, such as fruit trays or industrial packaging. This flexibility allows businesses to diversify their product offerings without investing in additional machinery, improving profitability.

Moreover, some egg tray machines are equipped with modular components that allow for easy upgrades or adjustments. This means that as demand changes or new product specifications emerge, manufacturers can adjust their production lines accordingly with minimal downtime or investment.

Scalability for Growing Businesses

For businesses looking to scale operations, fully automatic egg tray machines are an ideal solution. It has a higher production capacity and less labor requirements. Therefore, no matter what egg tray making machine price you buy it at, it is suitable for both small businesses seeking to grow and large manufacturing plants seeking to improve efficiency.

As the company expands, additional machines can be integrated into the production line with relative ease. The ability to scale up production without needing to drastically increase the workforce or operational complexity is a key advantage of automation. This flexibility provides a solid foundation for long-term business growth, enabling manufacturers to respond effectively to rising market demands.

Conclusion

Investing in a fully automatic egg tray machine presents a multitude of advantages, from improved production efficiency to reduced labor costs and enhanced quality control. These machines not only provide a scalable solution for growing businesses but also offer environmental benefits through resource conservation and waste reduction. As the demand for eco-friendly packaging continues to rise, manufacturers equipped with automated egg tray production systems will be well-positioned to meet this need while maintaining high operational efficiency and profitability.