In an era where sustainability and waste reduction are paramount, the paper egg tray making machine has emerged as a game-changer. By converting waste paper into durable and eco-friendly egg trays, these machines offer a solution that not only addresses waste management but also supports sustainable packaging practices. This blog delves into the intricacies of paper egg tray making machines, exploring their operation, benefits, market trends, and the challenges and opportunities they present.

Understanding Paper Egg Tray Making Machines

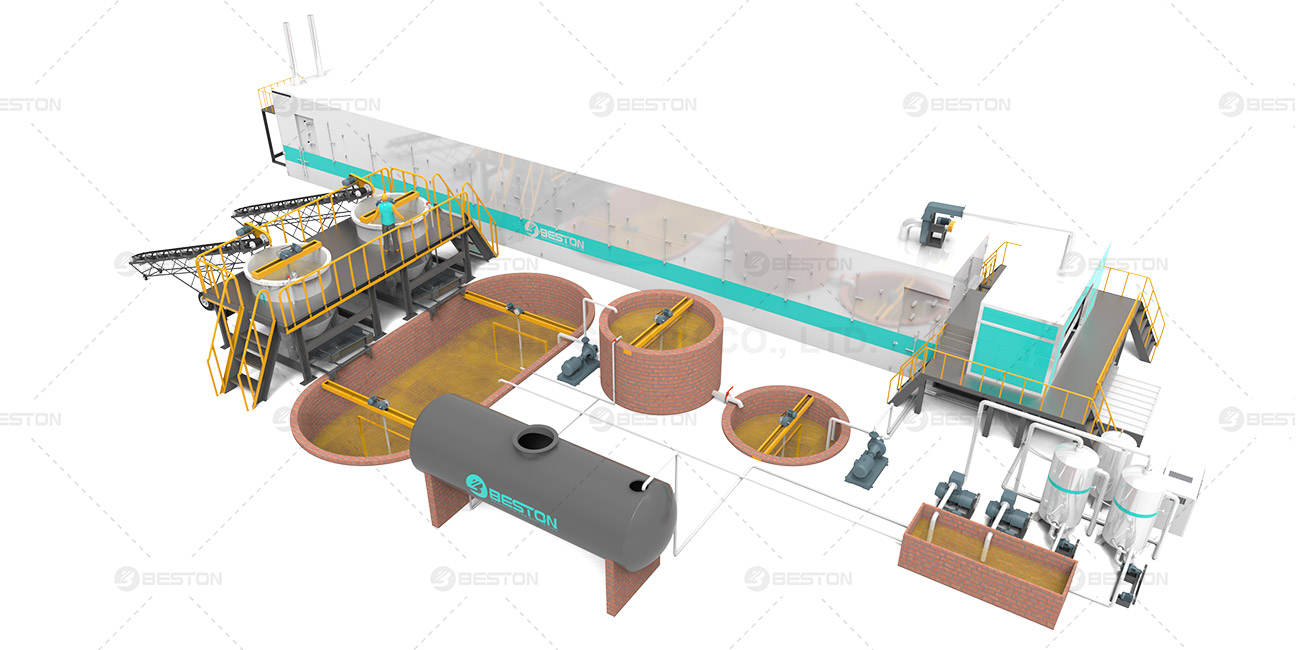

A paper egg tray making machine is a specialized piece of equipment designed to manufacture egg trays from recycled paper. The process involves several stages, including pulping, molding, drying, and packing. Here’s a breakdown of each stage:

1. Pulping: In the pulping stage, waste paper is mixed with water to form a pulp slurry. This process involves mechanical agitation to ensure the paper fibers are thoroughly broken down and suspended in water, creating a homogenous pulp mixture.

2. Molding: The pulp slurry is then transferred to the molding machine, where it is shaped into trays using molds. Vacuum suction removes excess water, leaving behind a wet egg tray. The design of the molds can be customized to produce trays of different sizes and shapes to accommodate various types of eggs or other products.

3. Drying: The wet trays are subsequently dried to remove moisture and increase their strength. Drying can be accomplished using natural sunlight, hot air ovens, or conveyor drying systems, depending on the scale of production and local conditions.

4. Packing: Once dried, the egg trays are ready for packing and distribution. They can be stacked and packed for storage or transport, ensuring they reach customers in good condition.

Advantages of Paper Egg Tray Making Machines

The adoption of paper egg tray making machines offers a myriad of benefits, particularly in terms of environmental sustainability, economic viability, and operational efficiency.

1. Environmental Benefits:

- Waste Reduction: By recycling waste paper into egg trays, these machines significantly reduce the amount of paper waste that ends up in landfills. This contributes to a reduction in overall waste and promotes a circular economy.

- Sustainable Packaging: Paper egg trays are biodegradable and compostable, making them an eco-friendly alternative to plastic trays. Their use helps in reducing plastic pollution and conserving natural resources.

- Energy Efficiency: Modern paper egg tray making machines are designed to be energy-efficient, minimizing energy consumption during the manufacturing process. This reduces the carbon footprint of production.

2. Economic Benefits:

- Cost-Effective Production: Using waste paper as raw material is cost-effective, as it is readily available and inexpensive. This lowers the overall production costs and increases profitability.

- Market Demand: There is a growing market demand for sustainable packaging solutions. Paper egg trays are favored by consumers and retailers alike for their environmental benefits, ensuring a steady market for producers.

- Job Creation: The operation and maintenance of pulp molding machine create employment opportunities, particularly in regions with high unemployment rates.

3. Operational Efficiency:

- Automation: Many modern machines are automated, reducing the need for extensive manual labor. Automation improves production speed and consistency, enhancing overall efficiency.

- Customization: Machines can be equipped with different molds to produce a variety of tray sizes and shapes, catering to diverse market needs.

- Scalability: Paper egg tray making machines are available in various capacities, from small-scale units suitable for startups to large-scale industrial machines. This scalability allows businesses to expand production as demand grows.

Market Trends and Opportunities

The market for paper egg tray making machines is influenced by several trends and opportunities, driven by the increasing focus on sustainability and waste management.

1. Rising Demand for Eco-Friendly Packaging: As consumers become more environmentally conscious, there is a growing demand for sustainable packaging solutions. Paper egg trays are preferred over plastic due to their biodegradability and minimal environmental impact. This trend is driving the adoption of paper egg tray making machines worldwide.

2. Government Regulations and Policies: Many governments are implementing regulations and policies to reduce plastic waste and promote recycling. These initiatives create a favorable environment for the adoption of paper egg tray making machines, as businesses seek to comply with environmental regulations.

3. Technological Advancements: Advancements in technology are enhancing the efficiency and functionality of paper egg tray making machines. Innovations such as energy-efficient drying systems, improved mold designs, and automation are making the production process more streamlined and cost-effective. See the pulp molding tableware machine is used to make paper plates.

4. Expansion in Emerging Markets: Emerging markets, particularly in Asia and Africa, are witnessing significant growth in the adoption of paper egg tray making machines. These regions have abundant waste paper resources and a growing need for sustainable packaging solutions, creating lucrative opportunities for manufacturers and suppliers.

5. Integration with Circular Economy Models: Businesses are increasingly integrating circular economy principles into their operations, focusing on waste reduction, recycling, and sustainable production. Paper egg tray making machines align perfectly with these models, offering a way to convert waste into valuable products and close the loop on material use.

Challenges in the Paper Egg Tray Making Industry

Despite the numerous benefits and opportunities, the paper egg tray making industry faces several challenges that need to be addressed to ensure its growth and sustainability.

1. Initial Investment: The cost of acquiring and setting up paper egg tray making machines can be high, particularly for small businesses and startups. Access to financing and support from government programs can help mitigate this barrier.

2. Quality Control: Ensuring consistent quality in the final product is crucial for market acceptance. Variations in raw material quality and machine performance can affect the durability and appearance of the egg trays. Implementing stringent quality control measures is essential.

3. Competition from Alternative Packaging: While paper egg trays are gaining popularity, they still face competition from plastic and foam trays, which are often cheaper to produce. Educating consumers and businesses about the environmental benefits of paper trays is important for increasing market share.

4. Raw Material Supply: The availability and cost of waste paper can fluctuate, affecting production stability. Establishing reliable supply chains and exploring alternative sources of raw material can help mitigate this risk.

5. Energy Consumption: Although modern egg carton making machine are designed to be energy-efficient, the drying process can still consume significant amounts of energy, especially in large-scale operations. Investing in energy-efficient technologies and renewable energy sources can reduce operating costs and environmental impact.

Case Studies and Success Stories

Several companies around the world have successfully implemented paper egg tray making machines, demonstrating their potential and impact.

1. Huhtamaki in India: Huhtamaki, a global leader in sustainable packaging solutions, has set up paper egg tray making facilities in India. By utilizing local waste paper, they produce high-quality egg trays for the Indian market, reducing plastic waste and supporting local economies.

2. Eggbox in South Africa: Eggbox, a South African company, has embraced paper egg tray making technology to produce eco-friendly egg trays for local poultry farms. Their success has been driven by strong demand for sustainable packaging and support from government initiatives promoting recycling.

3. RePulp in the Philippines: RePulp, a startup in the Philippines, uses mobile paper egg tray making units to convert waste paper from urban areas into egg trays. Their innovative approach has not only addressed waste management challenges but also created jobs and supported small-scale poultry farmers.

Future Outlook

The future of paper egg tray making machines looks promising, driven by increasing awareness of environmental issues, technological advancements, and supportive policies. Key trends shaping the industry include:

1. Increased Automation: Automation will continue to enhance the efficiency and scalability of egg tray production, reducing labor costs and improving product consistency.

2. Sustainable Innovations: Ongoing research and development will yield new technologies and materials that enhance the sustainability and performance of paper egg trays.

3. Expansion of Recycling Infrastructure: Improving waste collection and recycling infrastructure will ensure a steady supply of raw material for paper egg tray making, supporting industry growth.

4. Global Collaboration: Collaboration between governments, businesses, and NGOs will be crucial for promoting sustainable packaging solutions and addressing global waste management challenges.

5. Consumer Education: Educating consumers about the benefits of sustainable packaging will drive demand for paper egg trays and encourage more businesses to adopt this technology.

Conclusion

Paper egg tray making machines of Beston Group represent a significant step towards sustainable packaging and waste management. By converting waste paper into valuable products, these machines contribute to a circular economy, reduce environmental impact, and support economic development. As technology advances and market demand grows, the adoption of paper egg tray making machines is set to increase, offering a viable solution for businesses and communities worldwide. Embracing this technology is not only a smart business decision but also a commitment to a more sustainable and responsible future.